Oil separator – working principle

A high-speed centrifuge is a type of separator most often used on marine vessels and power generation stations to remove contamination in fuel and lubricating oils such as solids and water. It is imperative to carry out this treatment to prevent damage to engines and generators.

Working principle

The separation principle of high-speed centrifuge works on the differing specific gravity between two different liquids.

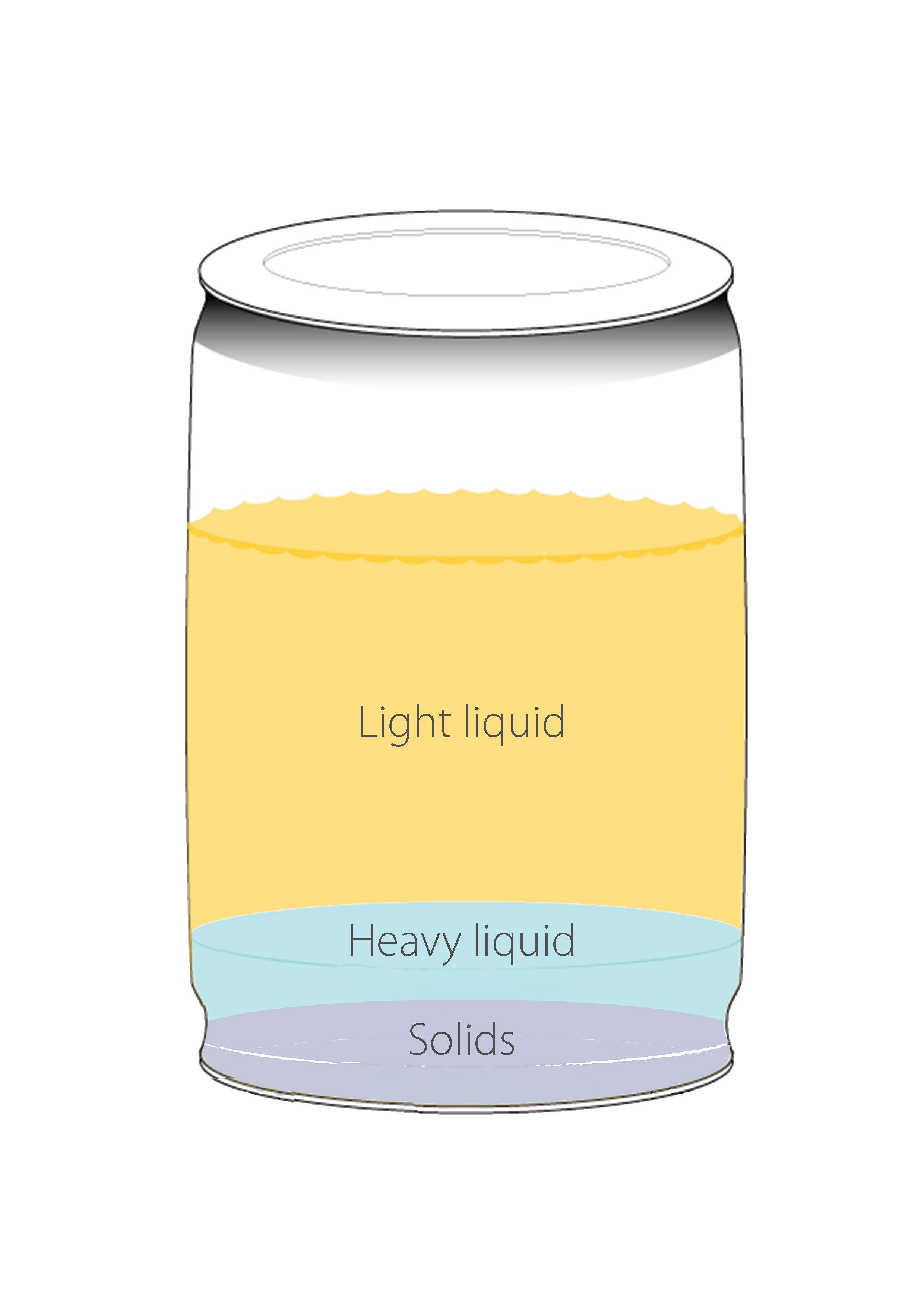

Gravity separation

To understand, we examine a beaker with oil, water and solids. After a settling period, water (heavy liquid) and solids get collected at the bottom while the oil (light liquid, non-emulsified) floats up top.

take note that the separation is due to gravity (or specific gravity). Heavy bunker fuel oil has an SG of about 0.95, diesel oil about 0.85 and fresh water has an SG of 1. Because of the difference in Specific Gravity, or SG, the oil will float on top of the water. The solid particles that is heavier than water will sink down. But by gravity, separation will take a long time. Furthermore, if the SG's of the mixture are very close, the oil and the water may not be able to separate very well.

Mathematically this process can be represented by:

Fs = ∏/6x D3 (ρw-ρo) g

Where Fs is the separating force, ρw is the density of water, ρo is the density of oil and “g” is gravitational force.

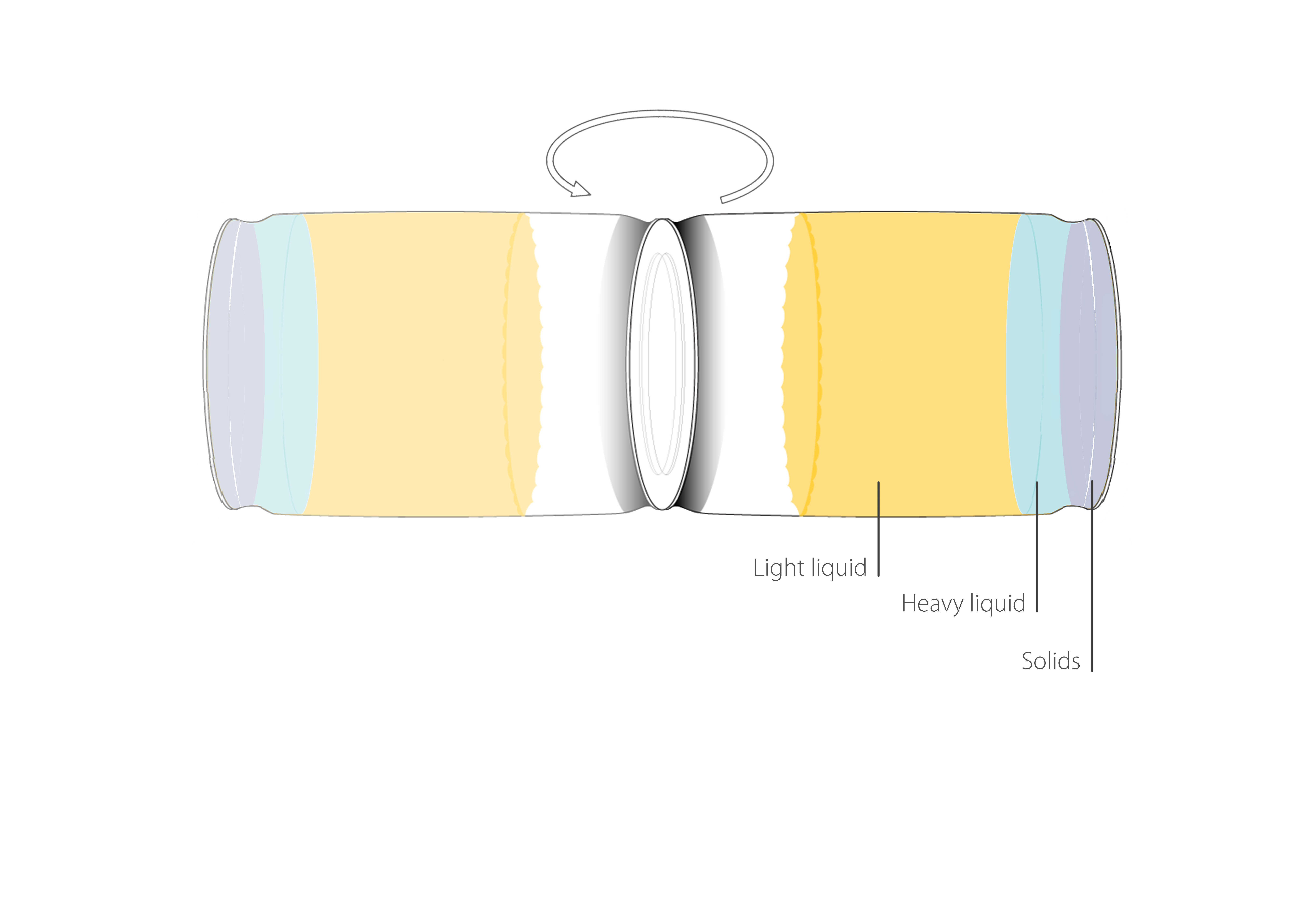

If we position the beaker on its side and rotate it fast, then the gravitational factor g will be replaced by the centrifugal force ω2 r, where ω2 is angular velocity of rotation and r is the effective radius. Fs = ∏/6x D3 (ρw-ρo) ω2 r.

Now the separating force will be much higher in the centrifuge as compare to a beaker.

Centrifugal separation

The separation effect is achieved much faster with a much greater force. As illustrated in the figure by positioning the beaker on its side and rotating it about the top as its axis. This movement forms the basic principle of centrifugal purifiers.

Oil separator

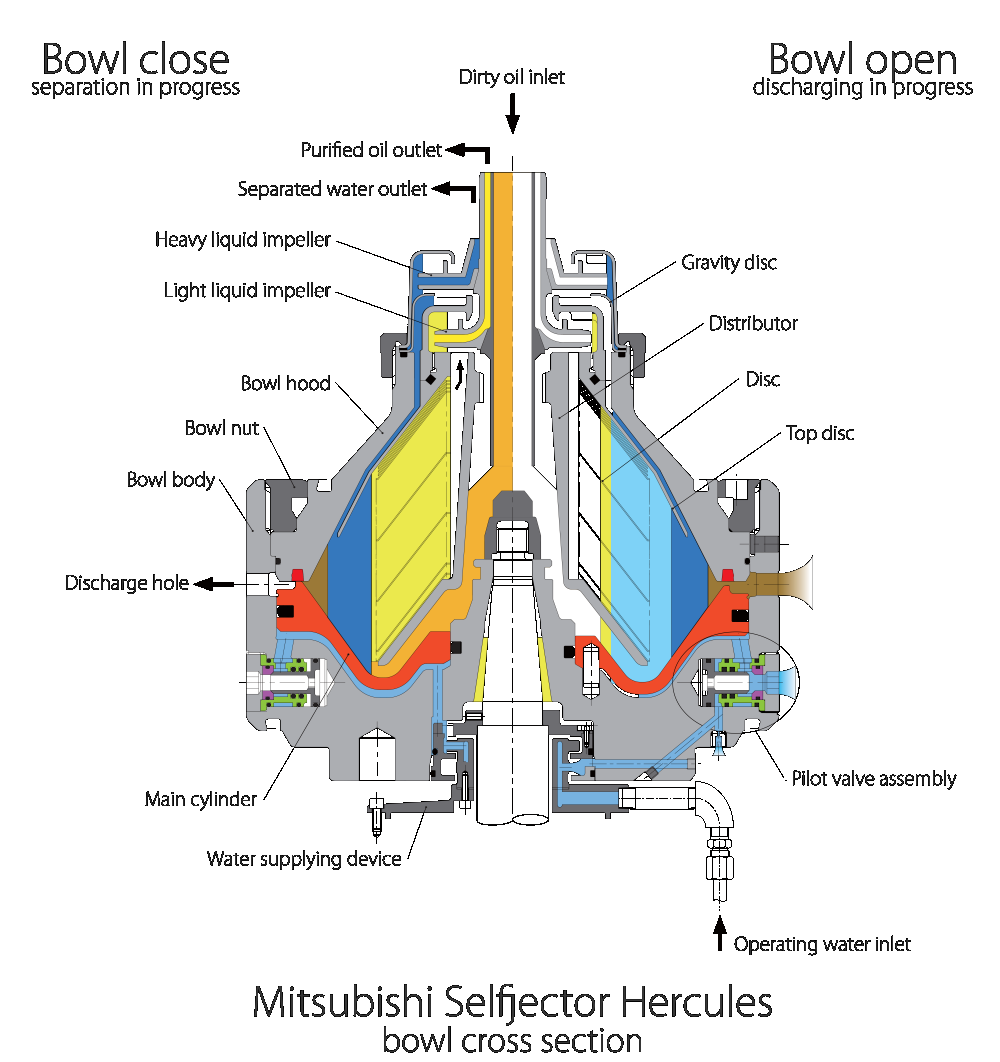

Through a system of gears, a centrifuge bowl is rotated to and maintained at high speeds. Oil to be cleaned is allowed to enter the bowl while it is rotating. The heavier components in the oil are thus forced outwards. The solid particles that are too fine to be removed by filtration are forced towards the circumference of the bowl.

Below is an illustration of the process during operation of the Mitsubishi Selfjector Hercules Series oil separators.

The oil should also be heated pre-feed to lower the SG of the oil. The difference in SG's between the oil and the water will thus be wider; making for better separation between the oil and the water.

Oil purifiers usually maintain a layer of water inside the bowl to act as a seal for the oil known as sealing water. Without it, the oil will flow out together with the contaminants.

If removal of water is not needed, the centrifuge can be modified so that no water layer is needed. The centrifuge then becomes a clarifier.

|

More information

|

|

|

|

|

Address

Industmarine Engineers

32 Toh Guan Road East

#01-09 Enterprise Hub

Singapore 608578

32 Toh Guan Road East

#01-09 Enterprise Hub

Singapore 608578

Contact No : 6774 6220

Email : enquiry@industmarine.com

About Us

Industmarine Engineers’ continual distinction in embodying our core philosophies of innovation, the human touch and active engagement has helped establish our company as a regional leader for providing products and services pertaining to the marine industry.

Read More

Read More

© 2017 Industmarine | All Rights Reserved